走进智慧钢城

日前,工信部、国家发改委、生态环境部三部委联合发布的《关于促进钢铁工业高质量发展的指导意见》提出,力争到2025年,钢铁工业基本形成布局结构合理、资源供应稳定、技术装备先进、质量品牌突出、智能化水平高、全球竞争力强、绿色低碳可持续的高质量发展格局。意见重点列出了“大力发展智能制造”的任务目标,为我国钢铁行业推进智能化改造和数字化转型提供了更加宏观、全面的指导,为行业高质量发展提供了根本遵循。

站在新起点上,沙钢如何以智能制造为切口,实现向价值链高端攀升?

“一方面,创新传统产业的发展,加快钢铁智能制造;另一方面,开拓新兴‘数字经济’,推动企业战略转型。”沙钢集团党委书记、董事局常务执行董事、有限公司董事长沈彬表示,未来3-5年,沙钢将把“智改数转”作为推动企业再发展、再升级的核心举措,按照“总体规划、分步实施、需求驱动、效益优先”的原则,不断推进智慧沙钢建设,持续提高企业核心竞争优势。

一、抢占“智高点” 实施全过程智能化改造

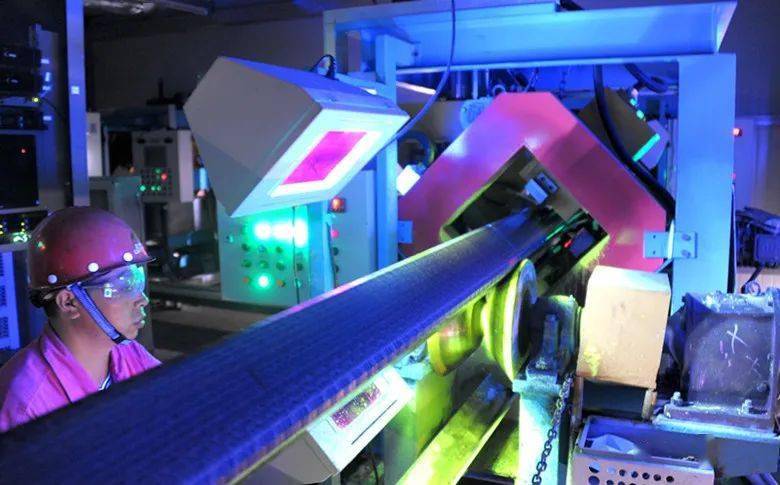

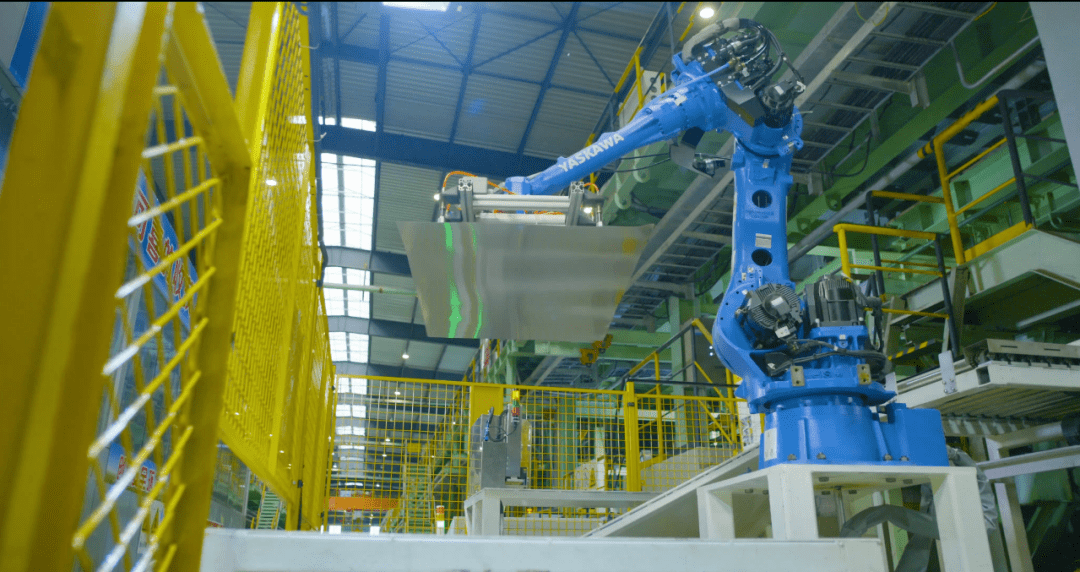

宽敞明亮的车间里,“训练有素”的工业机器人有条不紊地挥臂作业, 自动化流水线按照预先设定的程序进行流转、打包、贴标等工作…… 在智能制造大潮下 ,这样的场景在沙钢已屡见不鲜。

早在2018年,沙钢就提出智能制造五年规划,将“智能制造”提升到企业发展的战略高度,并形成了具体的实施计划,对智能制造的组织结构、技术架构、资源投入、人员配备等进行总体规划与部署,以智能制造项目的全面开展,支撑企业高质量发展进程。

经过近四年探索实践,拨开重重迷雾,沙钢摸索出了一条相对清晰的智能制造路径。以点带面,全面开花,一个个智能化项目在全产业链流程上蔓延开来,渐成“燎原之势”。目前,沙钢已建成1个国家级智能示范生产基地,7个省级智能示范车间,4个市级智能示范车间。

“以效率、效益为导向”是沙钢实施智能化改造的“锦囊妙计”。遵循这一工作思路,沙钢围绕计划、质量、设备、能源等八大业务主线推进产品、制造、服务全生命周期的各个环节及相应系统的优化集成,不断提升产品质量、效益和服务水平。

“在生产方面,我们的目标是实现产品研发模拟化、生产操作集约化,生产岗位无人化,生产调度智能化。”沙钢集团有限公司智能制造项目办负责人范冰说,在产品研发方面,沙钢致力打造国际首创的全流程数字化工艺研发仿真平台,发挥大数据、算法模型作用,实现炼钢、连铸、加热、轧制、冷却等工艺流程的数字化、可视化和智能化,加快新产品投向市场的速度。在生产操作方面,先后完成了8个管控中心建设,形成了公司+分厂的二级集中生产管控模式,实现了生产、质量、能环、设备、安全等方面的管理提升,大大提高了生产效率,今年将继续在全公司推广,实现全覆盖。在无人化及生产调度方面,加大项目实施,助力高效集约生产。

“‘机器大脑’可以进行自我‘健康’管理,遇到情况会自动报警、提示,我们再也不需要跑去现场人工点检了!”超薄带车间设备管理员刘宁感慨颇多。这个“机器大脑”就是目前正在全公司推广应用的设备在线监测与诊断系统,通过在设备上安装传感器,实时进行“切脉”,跟踪设备“健康”状况,实现了设备维护维修由“点检定修”向“智能运维”的转变,目前沙钢多条生产线均安装了该系统,有效保证了设备的高效稳定运行。

“在能源管理方面,我们做到了能源计量数据全部在线实时计量。”范冰表示,一方面通过对各类能源的在线计量,为生产运行调度提供数据支撑,为管理人员提供降本和治理挖掘平台,实现平衡经济用能;另一方面,通过在线监测各类能源的压力、流量等参数值,来保证用能的安全、高效。

此外,沙钢将逐步实施产品质量在线预判定,工艺参数在线自学习、自优化、自调整,检化验智能化,实现质量全过程可追溯;对每个物料设置电子标签,并实时跟踪动向,实现物流从原料到成品的全过程跟踪。

二、寻找“发力点” 推进全流程数字化转型

由制造迈向“智造”,沙钢前进的步伐愈加坚定、铿锵有力。然而,仅仅依靠智能制造装备还不够。从原料入厂到投入生产再到产品发运,大量的数据在这个过程中产生,如何有效运用这些数据,发挥其在钢铁生产中的价值?

沙钢紧紧围绕集团发展战略及企业实际,开展平台统一、数据体系治理、全面集成三大方面工作,并将之作为数字工厂建设新的发力点。

“沙钢对‘智改数转’的投入不设上限,从资金上来保证项目的推进和落地。”沈彬说。

2021年,沙钢大手笔投入4000万元,打造集团“人”“财”“物”数字化管控平台,着力提升集团业务数字化的广度和深度,实现业财税一体化,采购、营销业务线上化,上下游企业供应链业务协同化,打造企业共同发展生态圈。同时,沙钢通过建立集团数字化的管控体系,进一步提升业务的透明度,提升风险管控能力,最终实现业务可视、可管、可控。

步入沙钢铁前管控中心,一股浓浓的智慧化气息扑面而来。1800平方米的大厅里,数十块电子大屏幕上动态显示着铁前系统不同生产工序的实时监测画面,调度员轻轻点击鼠标,通过一键发送指令,便完成与生产现场的调度协调。据了解,这些生产数据将通过生产调度等系统,向上对接数字化经营管理平台,向下对接各数字化、智能化产线,全面实现公司、分厂两级的数字化大生产调度。

这只是沙钢数字化转型进程中的一隅。在生产全流程数字化建设方面,沙钢对脱硫-炼钢-连铸-开坯-热轧-冷轧全工序生产线实行了精益管理系统+MES系统质量管控模式的优化改造,实现了工艺标准从MES自动下发、质量监控数据自动采集、质量在线技监、实时报警、闭环处理等功能。

实现“双碳”目标同样离不开数字化技术的支撑。沙钢构建环保监测系统,实现了所有环保监测点的实时监视、历史曲线展示、实时报警,确保颗粒物、二氧化硫等指标全部达到超低排标准要求。同时,搭建能源智能管控优化系统,实现了多能源介质的综合平衡及节能减排、降本高效的目标。

“数字化转型,数据是关键,只有数据得到有效的治理,才能长期可持续地支撑沙钢数字化转型。”沙钢计算机应用中心相关负责人黄嘉辰表示,沙钢从组织架构,制度规范,数据标准、主数据、数据指标库、数据平台六大方面全力开展数据治理。通过近年来的推进建设,搭建了包含客商、物料等32项关键编码的主数据平台,基本形成了覆盖生产、质量、营销、能环、安全等5大板块的沙钢数据体系,数据在沙钢已逐步成为资产。

此外,沙钢以数据体系为基础,分公司及分厂两级构建相应数据分析平台,充分挖掘数据价值。通过公司级数据分析平台的使用,公司各项业务关键痛点、难点的解决有了数据支撑,如通过大数据分析,有效提升质量管控水平,产品一次合格率提升了近1%;通过分厂级数据分析平台的使用,将生产过程数据化,原有一些瓶颈性问题得到解决,如棒线生产异常问题得到了快速精确定位,异常停机时间环比下降,产量也得到了提升。

从设计到工艺、从计划到执行、从生产到发运,高效率、高效益的背后,折射出的是沙钢在数字化道路上的勇于探索和务实笃行。

三、培育“创新点” 打造数字经济“新蓝海”

不管是实施智能化改造占领“智高点”,还是推进数字化转型寻找“发力点”,都需要培养“创新点”。

2021年7月6日,苏州市召开智能化改造和数字化转型半年度工作推进会,对沙钢等企业创新开展“智改数转”工作予以表彰,授予“苏州市智能化改造和数字化转型标杆企业”称号。

“在服务好钢铁企业的同时,向工业企业拓展,为中小型企业提供全产业链、全生命周期的‘智慧制造’服务,同时布局大数据产业,从IDC服务向信息服务发展,为城市提供智慧安防、智慧环境、智慧能源、智慧物流、智慧金融等综合性解决方案,向智慧城市服务商转型,开拓‘数字经济’新蓝海。”沈彬在会议交流发言中描绘出未来沙钢数字经济“全景图”。

为增强企业自主数字化转型技术能力,沙钢成立了江苏沙钢高科信息技术有限公司。成立之前,这个团队已具有20多年的信息化实施经验,牵头承担过国家863计划SGCIMS工程建设、国家级智能制造新模式应用项目,以及企业大大小小的信息化建设工作,实施及运维的各个信息化系统为沙钢高质量发展提供了强有力的技术支撑。

打开市场之门的关键在于拥有自主核心技术能力及满足市场需求的产品。沙钢高科有关负责人表示,沙钢高科依托沙钢这个大平台,在支撑沙钢“智改数转”的同时,引进、吸收、培育云计算、大数据、工业互联、人工智能等关键核心技术,形成自主实施能力,全方位打造、打响沙钢高科品牌。

数字化转型关键在人才,人才的选、育、用、留也是一大重点。沙钢高科进一步创新人才管理机制,逐步培养了一批掌握制造技术,熟悉数字化、网络化、智能化技术,精通智能制造技术,具备实战能力,善于解决问题的智能制造技术人才,为企业数字化转型提供了雄厚的人才基础。

独木难成林,丛林遮蔽天。智能制造不是某个个体或某个部门的“独角戏”,而更应成为一场全员性的“大合唱”。

为调动全员推进智能制造积极性,沙钢着力构建智能制造生态环境。“一方面,我们自上而下,通过顶层设计,学习并借鉴同行业中智能制造的先进做法,结合企业的实际应用。另一方面,我们自下而上,通过摸排项目,激发基层员工的创新意识,加快推进智能制造步伐。”范冰说,今年初,沙钢又对标排查出200多个年度智能技改项目。

当数据联通现场,当虚拟走进现实,“智改数转”给企业带来的红利正在显现,而沙钢数字化转型的浩瀚征途才刚刚开始。5G技术、大数据、人工智能等前沿技术的应用将为企业插上创新翅膀,助力企业信息化、自动化、数字化、智能化的升级转型,展现出绿色、智能、创新的高质量发展新格局。

翻译:

Walk into the smart Steel City

Recently, the Ministry of Industry and Information Technology, the National Development and Reform Commission, the Ministry of Ecology and Environment jointly issued the “Guidance on promoting the high-quality development of the iron and steel industry”, and strive to 2025, The iron and steel industry has basically formed a high-quality development pattern featuring reasonable layout structure, stable supply of resources, advanced technology and equipment, outstanding quality brands, high intelligence level, strong global competitiveness, green, low-carbon and sustainable development. The opinions list the task goal of “vigorously developing intelligent manufacturing”, provides more macroscopic and comprehensive guidance for promoting intelligent transformation and digital transformation of Chinese iron and steel industry, and provides fundamental compliance for high-quality development of the industry.

Standing at a new starting point, how does Shagang take intelligent manufacturing as the incision to realize the climb to the high-end value chain?

“On the one hand, we will innovate the development of traditional industries and accelerate intelligent manufacturing of iron and steel. On the other hand, to explore the emerging ‘digital economy’ and promote the strategic transformation of enterprises.” Shen Bin, Secretary of the Party Committee of Shagang Group, executive director of the Board of Directors and chairman of the company, said that in the next 3-5 years, Shagang will take “changing the number of wisdom” as the core measure to promote the re-development and re-upgrading of the enterprise. In accordance with the principle of “overall planning, step by step implementation, demand-driven, benefit first”, we will constantly promote the construction of smart Shagang and continue to improve the core competitive advantage of the enterprise.

1. Seize the “intelligent high point” to implement the whole process of intelligent transformation

In the spacious and bright workshop, the “well-trained” industrial robots work methodically, and the automatic assembly line carries out the flow, packaging, labeling and other work in accordance with the pre-set procedures… Under the tide of intelligent manufacturing, such scenes have been common in Shagang.

As early as 2018, Shagang put forward a five-year plan for intelligent manufacturing, elevating “intelligent manufacturing” to a strategic height of enterprise development, and formed a specific implementation plan, overall planning and deployment of intelligent manufacturing organizational structure, technical framework, resource investment, staffing, etc., in order to fully carry out intelligent manufacturing projects and support the high-quality development process of enterprises.

After nearly four years of exploration and practice, Shagang has explored a relatively clear path of intelligent manufacturing. To point with the surface, full bloom, one intelligent project in the whole industrial chain process spread, gradually become a “prairie fire”. At present, Shagang has built 1 national intelligent demonstration production base, 7 provincial intelligent demonstration workshops, 4 municipal intelligent demonstration workshops.

“Efficiency, benefit oriented” is the implementation of intelligent transformation of Shagang “a trick up one’s sleeve”.

Following this working idea, Shagang promotes the optimization and integration of all links and corresponding systems in the whole life cycle of products, manufacturing and services by focusing on the eight main business lines of planning, quality, equipment and energy, and constantly improves product quality, efficiency and service level.

“In terms of production, our goal is to achieve analog product research and development, intensive production operations, unmanned production positions and intelligent production scheduling.” Fan Bing, head of intelligent manufacturing Project Office of Shagang Group Co., LTD., said that in terms of product research and development, Shagang is committed to creating the world’s first digital process research and development simulation platform, play the role of big data, algorithm model, realize the digitalization, visualization and intelligence of steel making, continuous casting, heating, rolling, cooling and other processes, and accelerate the speed of new products to the market.

In terms of production operation, it has completed the construction of 8 control centers successively, forming the two-level centralized production control mode of the company + branch factory, realizing the improvement of management in production, quality, energy, equipment, safety and other aspects, and greatly improving production efficiency. This year, it will continue to be promoted in the whole company to achieve full coverage. In the aspect of unmanned and production scheduling, we will increase project implementation to help efficient and intensive production.

“The ‘machine brain’ can carry out self-‘ health ‘management, and it will automatically alarm and prompt when encountering situations.

We no longer need to go to the scene to manually spot check!” Ultra-thin belt workshop equipment manager Liu Ning feeling a lot. This “machine brain” is the online monitoring and diagnosis system of equipment that is being promoted and applied in the whole company. By installing sensors on the equipment, real-time pulse sensing can be performed to track the “health” status of the equipment, which realizes the transformation of equipment maintenance from “point verification repair” to “intelligent operation and maintenance”. At present, several production lines of Shagang have installed this system. Effectively ensure the efficient and stable operation of the equipment.

“In terms of energy management, we have achieved online real-time metering of all energy metering data.” Fan Bing said, on the one hand, through the online measurement of all kinds of energy. It provides data support for production operation and scheduling. And provides a cost reduction and management mining platform for managers. So as to achieve the balance of economic energy use. On the other hand, through online monitoring of various energy pressure, flow and other parameter values, to ensure the safety and efficiency of energy use.

In addition, Shagang will gradually implement online pre-judgment of product quality. Online self-learning, self-optimization, self-adjustment of process parameters, intelligent testing and testing, to realize the traceability of the whole process of quality; Electronic labels are set for each material, and real-time tracking of the movement, to achieve the whole process of logistics tracking from raw materials to finished products.

2. Find “power points” to promote the digital transformation of the whole process

From manufacturing to “intelligent manufacturing”, Shagang’s pace of progress is more firm, sonorous and powerful. However, relying on intelligent manufacturing equipment alone is not enough. From raw materials into the factory to put into production and then to product delivery. A large number of data generated in this process, how to effectively use these data, play its value in steel production?

Shagang closely around the group’s development strategy and the actual situation of the enterprise, to carry out the platform unification, data system governance, comprehensive integration of three aspects of the work, and as a new strength of the construction of digital factory.

“Shagang does not set an upper limit on the investment of ‘wise change number turn’. And guarantees the promotion and landing of the project from the funds.” Shen Bin said.

In 2021, Shagang invested 40 million yuan to build the digital management and control platform of “people”, “finance” and “things” of the group, focused on improving the breadth and depth of the digital business of the group, realizing the integration of finance and taxation, the online procurement and marketing business, the synergy of supply chain business of upstream and downstream enterprises, and creating an ecological circle of common development of enterprises. At the same time, by establishing the group’s digital management and control system, Shagang further improves the transparency of the business. Improves the ability of risk management and control, and finally realizes the visible, manageable and controllable business.

Stepping into the front control center of Shairon & Steel, a thick breath of wisdom comes at you.

In the 1,800-square-meter hall, dozens of large electronic screens dynamically display real-time monitoring pictures of different production processes of Tieqian system. Dispatchers click the mouse gently and send instructions with one button to complete the scheduling and coordination with the production site. It is understood that these production data will be connected to the digital operation and management platform upward and each digital and intelligent production line downward through the production scheduling system. So as to fully realize the digital large-scale production scheduling at two levels of the company and the branch factory.

This is just a corner of Shagang’s digital transformation process. In terms of the digital construction of the whole production process, Shagang has implemented the optimization and transformation of the quality control mode of lean management system +MES system for the whole production line of desulfurization – steelmaking – continuous casting – billet – hot rolling – cold rolling, realizing the functions of automatic issuing of process standards from MES, automatic collection of quality monitoring data, online quality technical supervision, real-time alarm, closed-loop processing and so on.

The realization of the “double carbon” goal is also inseparable from the support of digital technology. Shagang builds environmental protection monitoring system to realize real-time monitoring, historical curve display and real-time alarm of all environmental protection monitoring points, to ensure that the indicators. Such as particulate matter and sulfur dioxide all meet the ultra-low emission standard requirements. At the same time, the intelligent control and optimization system of energy is built to achieve the comprehensive balance of multiple energy media and the goals of energy saving, emission reduction, cost reduction and high efficiency.

“For digital transformation, data is the key.

Only when data is effectively managed, can it sustainably support the digital transformation of Shagang in a long term.” Huang Jiachen, the relevant person in charge of Shagang Computer Application Center, said that Shagang has carried out data governance from six aspects:. Organizational structure, system and standard, data standard, master data, data index database and data platform. Through the promotion and construction in recent years, the main data platform including 32 key codes of merchants and materials has been built. And a data system covering production, quality, marketing, energy and safety has been basically formed. Data has gradually become an asset in Shagang.

In addition, based on the data system, Shagang builds the corresponding data analysis platform at the two levels of branches and factories to fully tap the value of data. Through the use of company-level data analysis platform. The key pain points and difficulties of the company’s various businesses have been solved with data support. For example, through big data analysis, the quality control level has been effectively improved. And the first-pass rate of products has increased by nearly 1%. Through the use of the data analysis platform at the branch factory level, the production process is datalized. And some existing bottleneck problems are solved. Such as the abnormal rod production is quickly and accurately located. Abnormal downtime is reduced month-on-month, and the output is also improved.

From design to process, from planning to implementation, from production to delivery. High efficiency and high efficiency reflect the courage of Sand Steel in the digital road exploration and pragmatic practice.

3. Fostering “Innovation Points” and Creating a “New Blue Ocean” for Digital Economy

No matter the implementation of intelligent transformation to occupy the “intellectual high point”. Or to promote the digital transformation to find the “power point”, we need to cultivate the “innovation point”.

On July 6, 2021, Suzhou held the semi-annual Promotion meeting of intelligent Transformation and digital transformation. Which commended Shagang and other enterprises for their innovative work of “intelligent transformation and digital transformation” and awarded them the title of “Benchmarking Enterprise of Intelligent Transformation and digital Transformation in Suzhou”.

“While serving the iron and steel enterprises well. We expand to industrial enterprises, provide the whole industrial chain and the whole life cycle of ‘smart manufacturing’ services for small and medium-sized enterprises. And at the same time layout the big data industry, from IDC service to information service development. To provide the city with smart security, smart environment, smart energy, smart logistics, smart finance and other comprehensive solutions. We will transform into smart city service providers and open up a new blue ocean of ‘digital economy’.” Shen Bin in the meeting exchange speech described the future Shagang digital economy “panorama”.

In order to enhance the technological capability of independent digital transformation, Shagang established Jiangsu Shagang Hi-Tech Information Technology Co., LTD.

Before its establishment, this team has more than 20 years of informatization implementation experience. It has taken the lead in undertaking the national 863 Program SGCIMS project construction. The national intelligent manufacturing new mode application project. And the enterprise informatization construction of large and small. The implementation, operation and maintenance of various informatization systems have provided strong technical support for the high-quality development of Shagang.

The key to open the door of the market is to have independent core technology capabilities and meet the market demand of products. The person in charge of Shagang High-tech said that relying on the big platform of Shagang, Shagang High-tech introduced. Absorbed and cultivated key core technologies such as cloud computing, big data, industrial interconnection and artificial intelligence while supporting Shagang’s “intellectual transformation”, formed independent implementation ability. And built and launched Shagang High-tech brand in an all-round way.

The key to digital transformation lies in talents, and the selection, education, use and retention of talents is also a major focus.

Shagang High-tech further innovates the talent management mechanism, and gradually trains a group of intelligent manufacturing technical talents who master manufacturing technology, are familiar with digital, networking, intelligent technology, proficient in intelligent manufacturing technology, have actual combat ability, and are good at solving problems. Which provides a strong talent base for the digital transformation of enterprises.

A single tree does not make a forest. Intelligent manufacturing is not an individual or a department of “monologue”, but should become a full member of the “chorus”.

In order to mobilize the enthusiasm of all staff to promote intelligent manufacturing. Shagang focuses on the construction of intelligent manufacturing ecological environment. “On the one hand, we top-down, through top-level design, learn and draw lessons from the industry’s advanced intelligent manufacturing practices, combined with the actual application of enterprises. On the other hand, from the bottom up, we stimulate the innovation consciousness of grassroots employees through the project, and accelerate the pace of intelligent manufacturing.” Fan Bing said that at the beginning of this year. Shagang has identified more than 200 annual intelligent technological upgrading projects.

When the data connection site, when the virtual into reality, “smart change number turn” to the dividend is showing. And Shagang digital transformation of the vast journey has just begun. The application of cutting-edge technologies such as 5G technology, big data and artificial intelligence will give enterprises wings of innovation, promote the upgrading and transformation of IT, automation, digitalization and intelligent enterprises, and show a new pattern of green, intelligent and innovative high-quality development.

免责声明:本网站安心库Anshinko (https://anshinko.com)内容主要来自原创、合作媒体供稿和第三方投稿,本文为本网站出于传播商业信息之目的进行转载发布,不代表本网站的观点及立场。本文所涉文、图、音视频、LOGO、软件、程序等资料之一切权利和法律责任归原作者所有和承担。本网站对此资讯文字、图片等所有信息的真实性不作任何保证或承诺,亦不构成任何购买、投资等建议,据此操作者风险自担。

任何单位或个人认为本网站中的内容可能涉嫌侵犯其知识产权或存在不实内容时,请及时通知本站,予以删除。

浙公网安备 33010602013084号

浙公网安备 33010602013084号